Shipping Control

Can You Prove 100% Loading Accuracy?

Warehouses across the world are using Zimark’s Shipping Control to ensure each pallet is loaded on to the correct truck, speed up loading times and record video evidence. Scroll down to find out how it works.

Our Trusted Partners

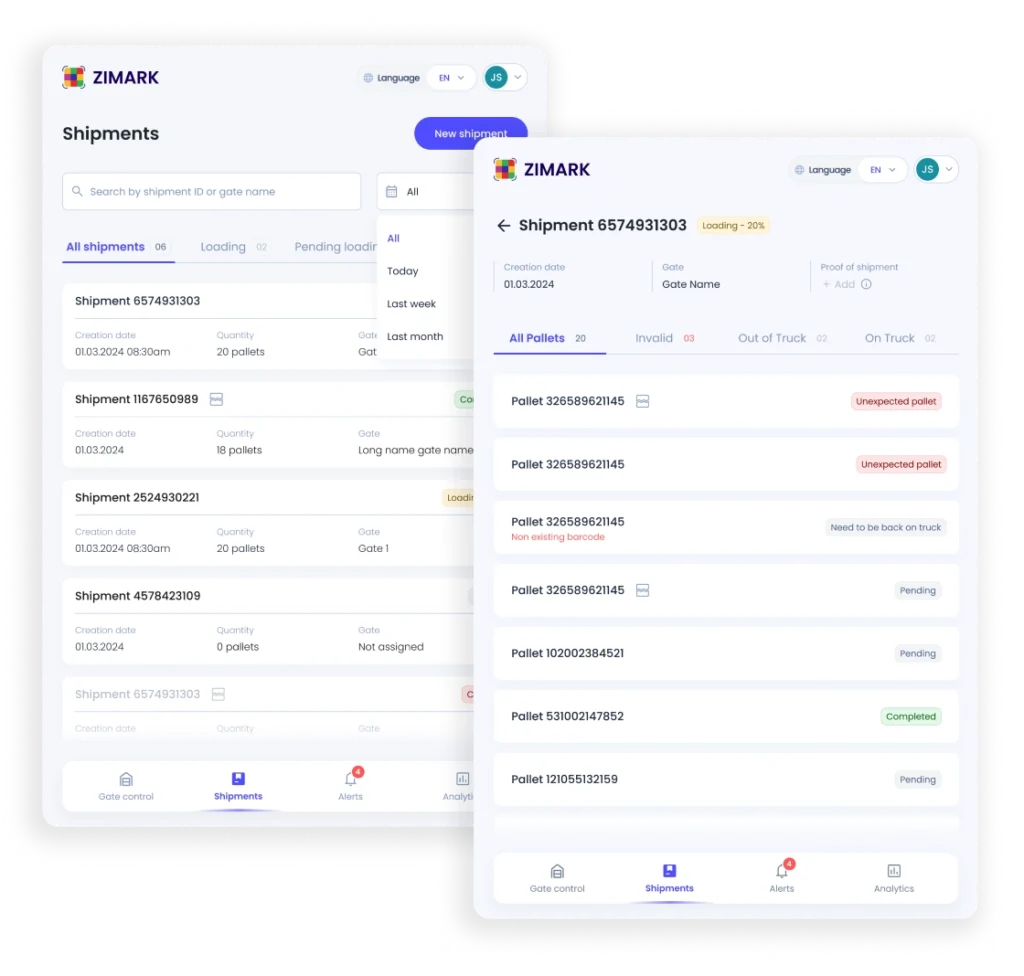

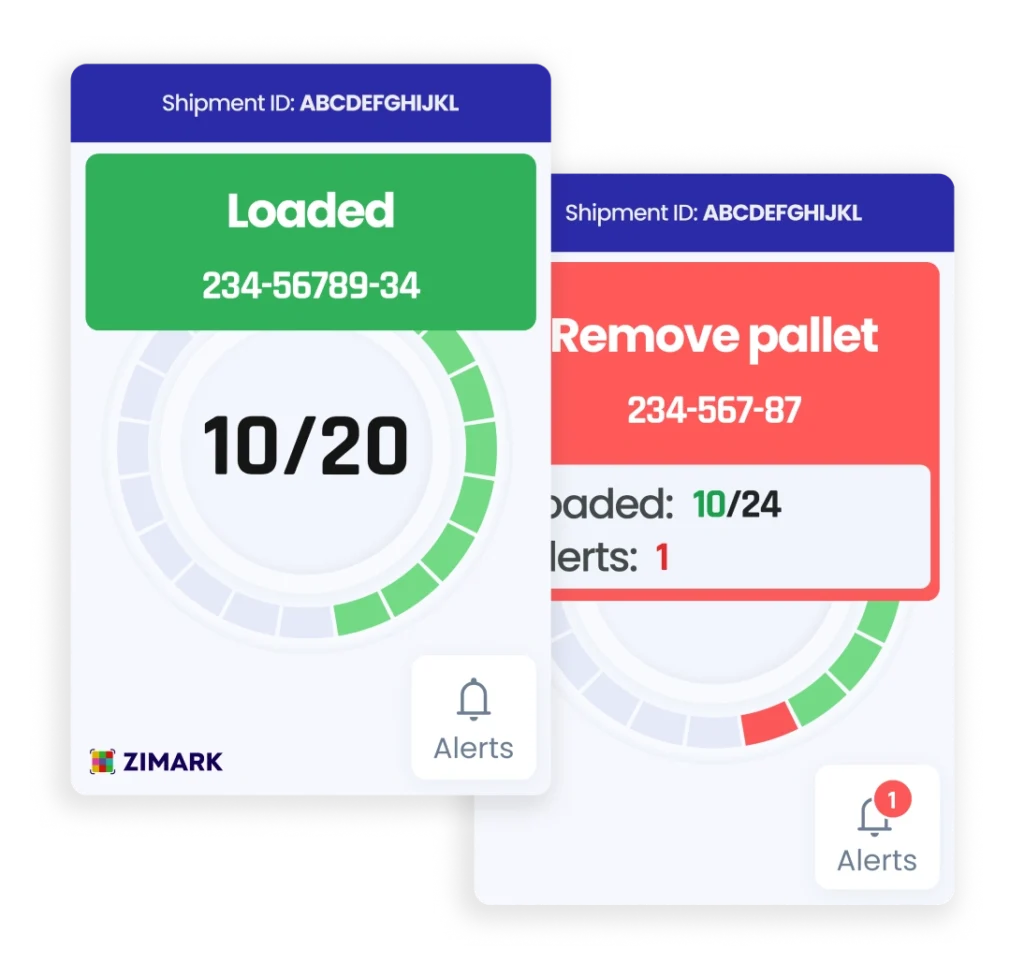

Fully Automated Load Verification

Upload your manifest as received from the customer and assign it to a loading bay. Smart cameras and AI computers verify that each pallet is meant to be on the truck, with no need for manual double-checking.

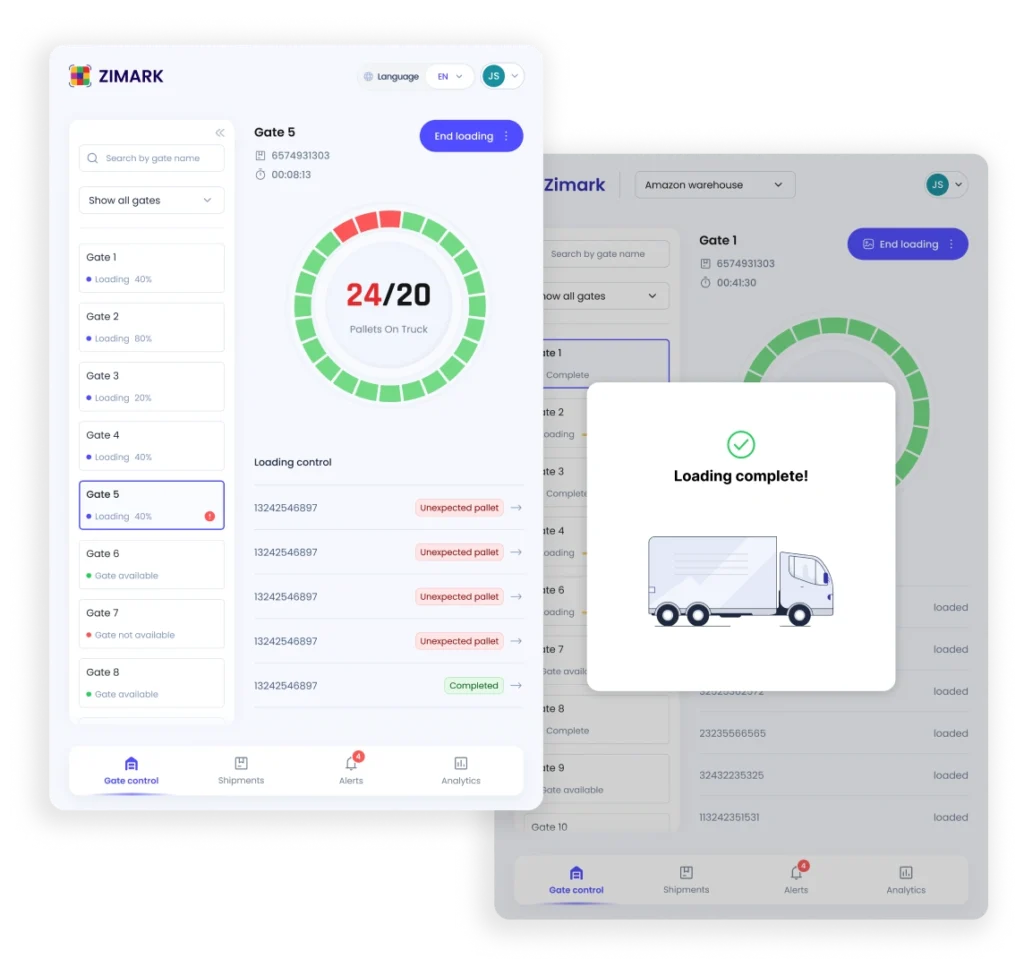

Manager Oversight of All Gates

Floor Managers and Warehouse Managers supervise all gates from wherever they are, with our friendly Operational App. Remotely approve/deny shipment completion and access live loading information from anywhere.

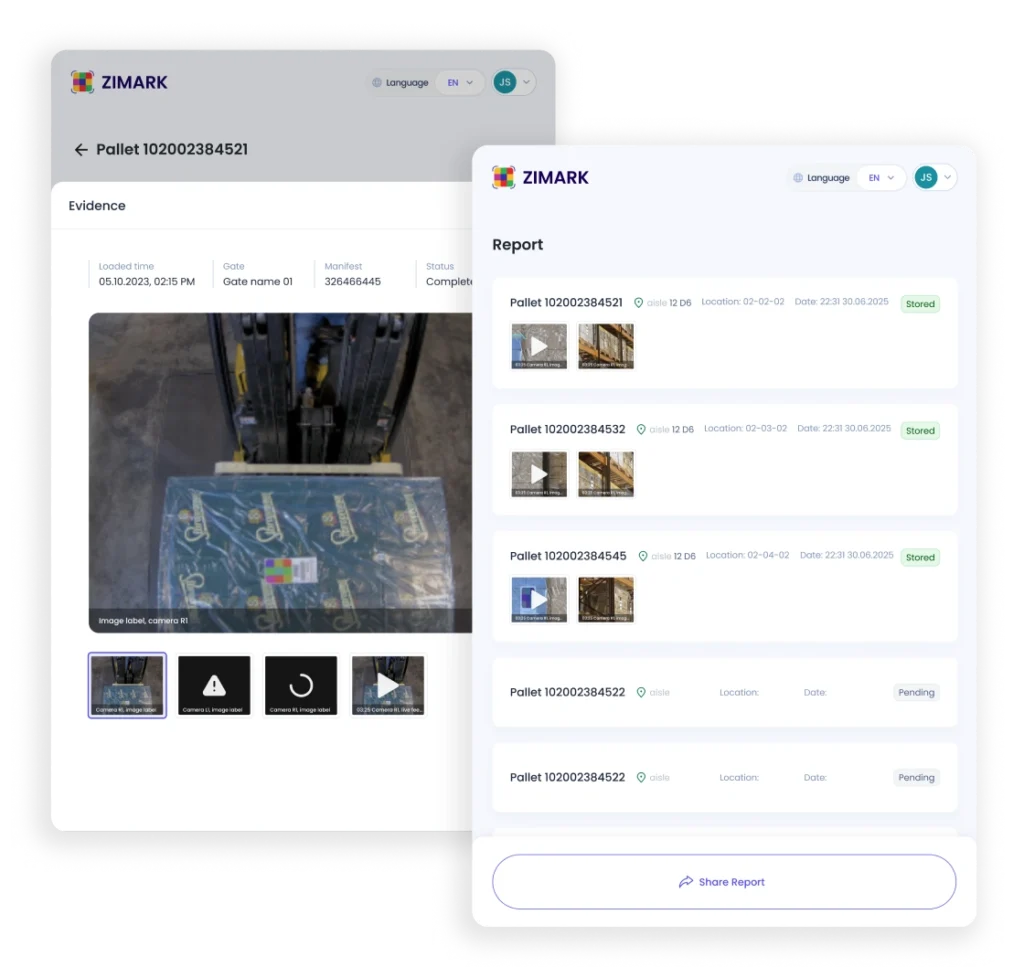

Resolve Claims in Seconds

Each pallet loaded isn’t just verified – it’s videoed and saved. Search by date, Pallet Number or Shipment ID, pull up the video and click “Share” to send straight to your customer.

Faster Loading Times

Turnaround more trucks, with less stress and greater efficiency, thanks to Zimark Shipping Control. By making less mistakes and reducing the staff needed to load a shipment, warehouses are increasing their loading capacity by 30%!

98% Isn’t Good Enough

Most warehouses double-verifying loads are 98% accurate. But 98% isn’t good enough in 2026, not when you’re shipping 5,000 pallets a month - that’s 1,200 mistakes every year. The gold standard is Five 9s - 99.999%. Only machine supervision can get you there.

The Old Way

Free Two-Day PoV

Interested in Shipping Control for your warehouse? Book a free “Proof of Value” with the Zimark team. We’ll set up Shipping Control on one gate for you to try it out on real-life shipments and get your team’s feedback.